Substrate

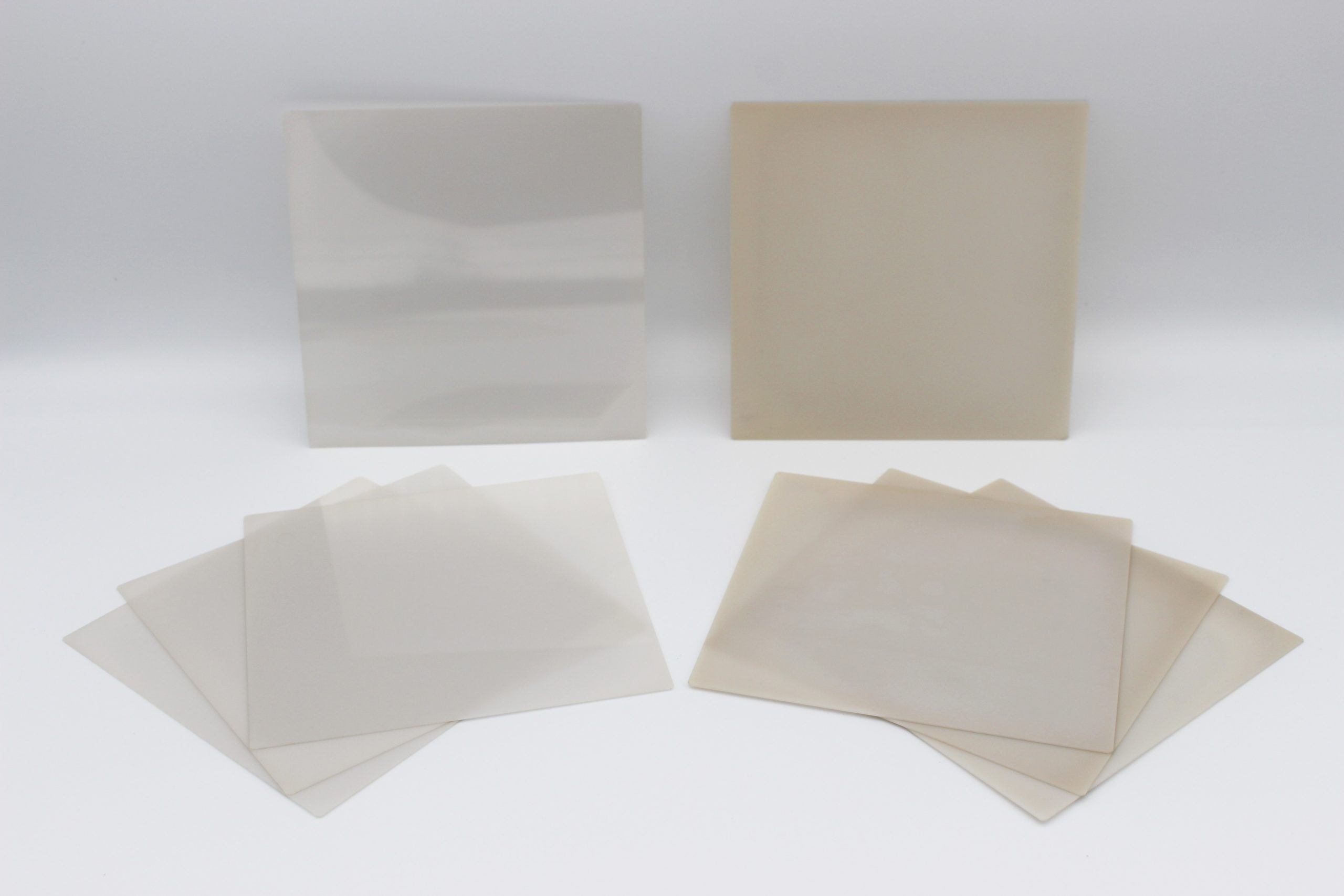

Aluminium nitride (AIN) ceramics

Furukawa Denshi provides substrates sliced from blocks manufactured through our sintering technology.

Aluminum nitride substrates achieve both high heat radiation and electrical insulating properties. They are used as heat radiation substrates for 5G-era power semiconductors and optical communication lasers, radiating heat while insulating.

With FAN-200 and FAN-230, which feature greater thermal conductivity than our general purpose-grade FAN-170, our substrates receive high marks as heat radiation substrates for electronic devices that require greater heat radiation.

As the substrates are manufactured through slicing of blocks, we are able to accept inquiries for large areas, thick material (1 mmt or greater), and small lots. We can provide surface roughness ranging from Ra = 1 μm to a mirror finish.

We are also developing products that feature greater thermal conductivity than FAN-230, and will continue providing high-quality substrates.

Characteristics (typical values)

| Item | Grade | |||

| FAN-170 | FAN-200 | FAN-230 | ||

| Thermal conductivity | W/m・K(RT) | 170 | 200 | 230 |

| Thermal emissivity | (100℃) | 0.93 | ||

| Thermal expansion coefficient | 10-6/℃(RT~400℃) | 4.5 | ||

| Insulation resistance | Ω・cm(RT) | >1013 | ||

| Dielectric strength | kV/mm(RT) | 15 | ||

| Dielectric constant | (1MHz) | 8.8 | ||

| Dielectric loss | 10-4(1MHz) | 5 | ||

| Flexural strength | MPa | 350 | ||

| Density | g/cm3 | 3.3 | ||

| Y(yttrium) | wt% | 3.4 | ||

Specifications

| External dimensions | Up to 200 mm□ |

| Plate thickness | 0.15~1mmt or more |

| Surface roughness | Ra≦0.8μm to mirror finishing |

| Laser processing/metallizing | Available as required |